RANIERO FORKLIFTS FROM

5t to 10t OF LOAD CAPACITY

ELECTRONIC AC TECHNOLOGY

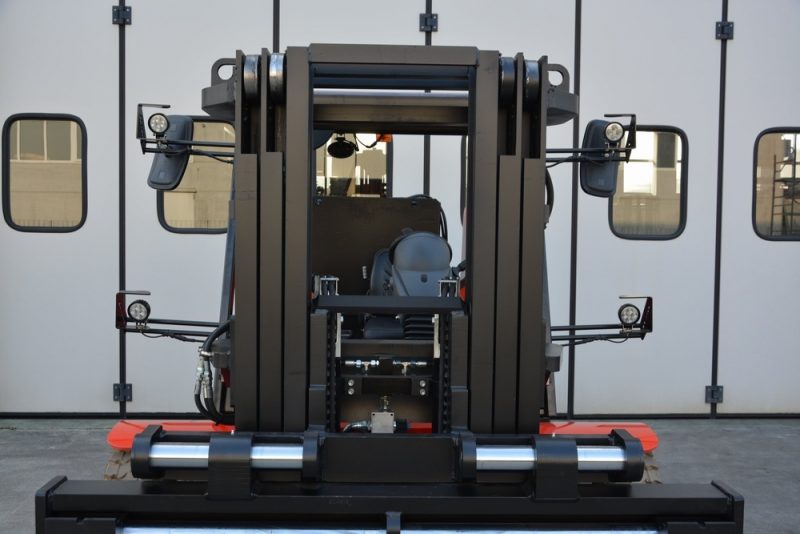

AC70-6 – A80-6 – AC80-9 – AC100L-6

7000 kg, 8000 kg, 8000 kg at 900 mm, 10000 kg – 15400 lbs, 17600 lbs, 17600 at 37\’, 22000 lbs

The AC Forklifts series from 7 to 10 tons are designed and developed to move large and heavy loads in tight spaces and in different climatic conditions.

Main characteristics:

• A safe workplace thanks to zero emissions, low noise levels, ergonomic access to the cabin, wide visibility for the operator.

• Using AC technology –ALTERNATING CURRENT– to manage the traction motor 32kW (80V) / 38kW (96V) / 45kW (120V) and the lifting pump motor 42kW (80V) / 48kW (96V) / 50kW (120V), improving performances, autonomy and longevity of charged battery.

• Reliability guaranteed by particularly robust frames and masts able to withstand external stresses.

• Safety during the shifting and handling of loads thanks to the electronic control of the hydraulic and traction functions.

• Recovery of energy on deceleration or the reverse direction phase.

• With the dynamic steering system, steering control is agile and precise.

• Quick and safe change with Devio Command or a double pedal.

• Comfortable cabin with 360° and overhead view.

• A safe braking system using Oil Bath Braking.

• Energy savings achieved by individually activated motors and lower energy costs compared to Diesel/LPG, with an economic return on investment in a short time.

• Fork carriage FEM4A, 3 hydraulic ways with piping plus 4th, 5th, 6th and more make the forklift more versatile for using equipment in different operating environments indoor/outdoor.

ACL60-6 – ACL65-6 – ACL70-6 – ACL80-6

6000 kg, 7000 kg, 8000 kg at 600 mm – 13200 lbs, 15400 lbs, 17600 lbs at 24′

The ACL Forklift Series is the best solution for short and frequent operations.

Main characteristics:

–HT (tilt cylinders above the roof) and CO (Compact length l2=3065 mm) Configuration that allows the ability to handle bulky loads in narrow aisle storage.

–Robust masts studied for a safe and stable load during the lifting phase without vibrations.

–Steering system, which facilitates forklift manoeuvres skilfully and combines precision and driving lightness.

–Comfortable cabin with a 360° and overhead view.

-A safe and ergonomic entry into the cabin with an optimal driver’s seat position.

–Rear battery positioning to facilitate a quick change.

–Recovery of energy during deceleration or the reverse direction phase.

-A safe braking system using Oil Bath Braking.

–Fork carriage FEM4A, 3 hydraulic ways with piping plus 4th, 5th, 6th and more, make the forklift more versatile for using equipment in different operating environments indoor/outdoor.

–AC Technology, twin traction motors, with a lifting and steering motor, allows for a significant reduction in consumption.

–Simple, efficient operator-forklift interaction and a rapid and precise response to every single activated command.

-A safe workplace thanks to zero emissions and low noise levels.

Sectors: paper, steel and aluminium, wood, logistic.

RH50 – RH60 – RH70

5000 kg, 6000 kg, 7000 kg at 600 mm load center – 11000 lbs, 13200 lbs, 15400 lbs at 24\’ load center

RH50 – 60 – 70 offer high performances and zero emissions.

Main characteristics:

•Developed on well-reinforced mast with well-weighted chassis, it represents a strong forklift and agile too.

•The 80V and 96V electronic management of bi-traction motors, lifting motor pump and steering, gives rapid of movements.

•Devio lever or bi-pedal brings a high standard ergonomic level to the operator.

•Grammer seat.

•High visibility from the cabin and thanks to external chains of mast.

• Intuitive control on display.

•Easy access to driving position.

•Line choice for reliability demonstrated when subjected to heavy loads and continuous work on multiple shifts.

•Stability of masts in the handling of voluminous goods.

•Flexibility in the use in indoor and outdoor areas, with different types of flooring.

•Fork carriage FEM4A, 3 hydraulic ways with piping plus 4th, 5th, 6th and more make the forklift more versatile for using equipment in different operating environments indoor/outdoor.

•SBE: Side battery extraction facilitates the driver to change it – option on request.

Fields of use: paper, steel and aluminium, timber, emptying containers, manufacturing, logistic.

C- CONTAINER FRIENDLY 5000 KG – 10000 KG

5000 kg to 10000 kg at 600 mm load center – 11000 lbs to 22000 lbs at 24\’ load center

Do you have low height limits to meet or have to work inside Containers? Range from 5 to 10 ton forklifts completed with the C-Container Friendly configuration.

This version comes on the need for who to load and unload containers. For those who need to operate in spaces with heights just over 2200 mm.

RH series 5000 kg – 6000 kg – 7000 kg:

- RH50 – 60 – 70 offer high performances and zero emissions.

- Line choice for reliability demonstrated when subjected to heavy loads and continuous work on multiple shifts.

- Flexibility in the use in indoor and outdoor areas, with different types of flooring.

AC series 7000 kg – 8000 kg – 8000 kg at 900 mm – 10000 kg:

- AC Forklifts series AC70-6 – 80-6 – 80-9 – 100L-6 were developed to move large and heavy loads in tight spaces and in different climatic conditions.

- Using AC technology –ALTERNATING CURRENT- to manage the traction motor 32kW (80V) / 38kW (96V) / 45kW (120V) and the lifting pump motor 42kW (80V) / 48kW (96V) / 50kW (120V), improving performances, autonomy and longevity of charged battery.

- Reliability guaranteed by particularly robust frames and masts able to withstand external stresses.

- Working in long and frequent operation shifts.

- Applications with special attachments – paper clamps, coil booms, multiple forks.

- Indoor/outdoor operations in different ground conditions.

- Quickly replacing battery by another forklift or a crane.